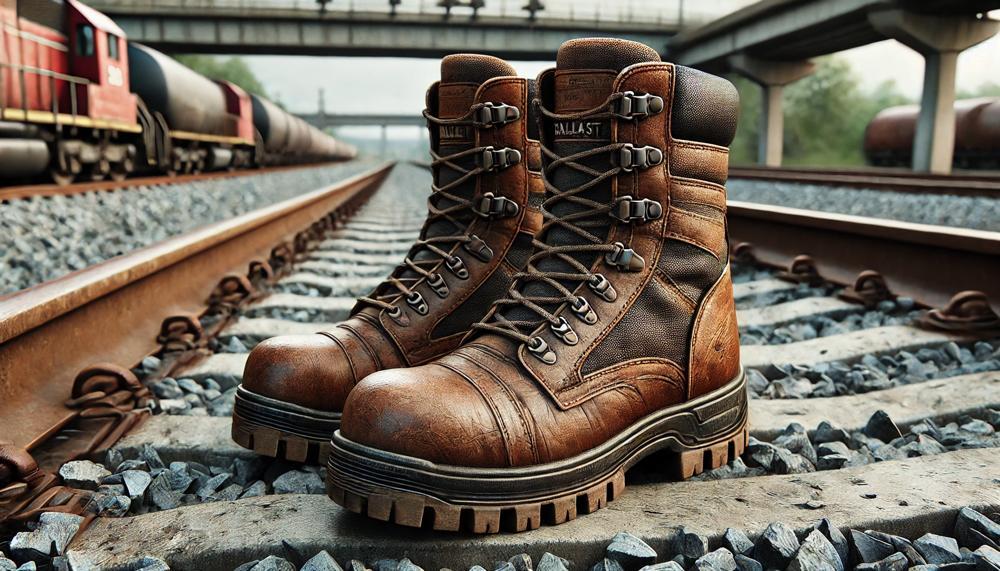

Are you working on railroad ballast and wondering if there are boots specifically designed for the job? Absolutely. The best boots for railroad ballast are a must-have, ensuring both safety and comfort as you navigate the rugged terrain of crushed stone. Here’s a quick rundown of what to look for and some top choices:

- Durability: The rough, uneven surface of railroad ballast demands boots that can withstand constant wear and tear. Look for tough materials that won’t easily break down.

- Sturdy Sole: Essential for stability and protection against sharp objects, a robust sole can make all the difference.

- Comfort: Long hours on your feet require boots with good cushioning and support to prevent fatigue and discomfort.

- Protection: Features like steel or composite toes can protect against heavy objects and other hazards.

With these key points in mind, let’s explore some top-rated boots for tackling the challenges of railroad ballast. From steel-toe work boots to lightweight hiking boots, we’ll cover options that combine durability, comfort, and safety to keep you going strong on the tracks. Dive in and find your perfect pair.

Best Boots For Railroad Ballast?

Contents

- 1 Best Boots For Railroad Ballast?

- 2 Types of Boots Suitable for Working on Railroad Ballast

- 3 Steel-Toe Work Boots: Durability and Protection

- 4 Composite-Toe Work Boots: Lightweight and Comfortable

- 5 Rubber Boots: Waterproof and Chemical-Resistant

- 6 Hiking Boots: Comfort and Traction on the Ballast

- 7 Wellington Boots: Convenience and Protection Against Wet Conditions

- 8 Conclusion

Choosing the best boots for railroad ballast involves several crucial considerations to ensure both safety and comfort during long hours of work. Here’s a detailed breakdown of the key factors to keep in mind:

| Feature | Description | Benefit |

| Safety Features | Steel toes, non-slip soles | Prevents injuries from impacts and slips |

| Durability | Leather or synthetic, reinforced stitching | Withstands harsh conditions, long-lasting |

| Comfort | Shock-absorbing insoles, padded collars | Reduces foot fatigue and discomfort |

| Waterproofing | Water-resistant materials | Keeps feet dry, prevents infections |

| Insulation | Materials that keep feet warm | Protects against cold, enhances comfort |

| Weight | Balance between protection and weight | Minimizes fatigue, improves comfort |

| Fit and Size | Correct fit, suitable for orthotics | Ensures comfort, prevents blisters and injuries |

Choosing the right boots for railroad ballast is critical for ensuring safety, comfort, and performance on the job.

Types of Boots Suitable for Working on Railroad Ballast

| Type of Boot | Key Features | Advantages |

| Steel-Toed Boots | Made with a reinforced steel toe cap, robust traction, and stability features. | Provides maximum protection against heavy impacts and is essential for safety on uneven surfaces like railroad ballast. |

| Composite Toe Boots | Constructed with non-metallic materials like Kevlar or carbon fiber, lightweight, and non-conductive. | Offers protection similar to steel-toed boots but with added comfort and reduced weight, making them suitable for long shifts. |

| Waterproof Boots | Features a waterproof membrane with insulation options, excellent traction for wet and slippery conditions. | Keeps feet dry and comfortable in adverse weather conditions, ensuring continuous protection and grip on slick surfaces. |

Each type of boot presents unique benefits that cater to the demanding conditions of working on railroad ballast. Steel-toed boots offer unrivaled protection, composite toe boots combine safety with comfort, and waterproof boots ensure dryness and stability in challenging weather. For workers on the railroad, selecting the right boot is not just about foot comfort; it’s about ensuring personal safety in a hazardous environment.

Steel-Toe Work Boots: Durability and Protection

Steel-toe work boots provide essential durability and protection for railway workers dealing with heavy ballast materials. The steel toe cap, designed to withstand significant impact, acts as a shield against falling objects, debris, and heavy equipment, protecting the worker’s feet from injuries.

Additionally, these boots are built to endure the harsh conditions of railway worksites, such as uneven surfaces and heavy loads, ensuring long-lasting performance.

| Durability | Protection | Support |

| Steel-toe boots are constructed to withstand the tough environment of railway worksites. The robust materials and reinforced stitching ensure that the boots can handle the daily wear and tear without breaking down. | The steel toe cap safeguards feet from falling ballast and equipment, significantly reducing the risk of fractures and other injuries. This protective barrier is crucial for workers frequently handling heavy materials. | Featuring slip-resistant soles, steel-toe boots provide superior traction on uneven surfaces. This reduces the risk of slips and falls, enhancing overall stability and balance during demanding tasks. |

| The durability extends the life of the boots, making them a cost-effective choice for railway workers who need reliable footwear for prolonged use. | Steel-toe caps distribute the weight of heavy loads evenly across the foot, reducing the chances of compression injuries like fractures or sprains, which are common in railway work. | The reinforced construction also prevents foot rolling or twisting, which can lead to sprains, enhancing the worker’s safety and performance on the job. |

Composite-Toe Work Boots: Lightweight and Comfortable

Composite-toe work boots offer an advantageous blend of comfort and protection, especially suited for the demanding conditions faced by workers on railroad ballast. Unlike their steel-toe counterparts, these boots utilize materials such as Kevlar, carbon fiber, or plastic in the toe area. This not only minimizes the weight but also ensures flexibility, crucial for mobility and comfort during long shifts on the uneven and rocky surfaces typical of railroad ballast. The lightweight nature of these boots reduces fatigue, making it easier for workers to navigate long distances and varied terrains without the burden of heavy footwear.

Moreover, the flexibility of the composite materials allows for more natural movement of the feet, which is vital for maintaining comfort during prolonged wear. These boots also incorporate features such as cushioned insoles and supportive midsoles, enhancing comfort and providing essential shock absorption. Such features are particularly beneficial on railroad ballast, where the risk of foot fatigue and injury is elevated due to the hard, uneven surfaces.

Protection is not compromised for lightness and comfort in composite-toe boots. They are designed to meet safety standards with high impact resistance and a solid compression rating, protecting against heavy falling objects and high-pressure impacts. This protective quality is complemented by additional safety features, including non-conductive materials that offer insulation against electrical hazards—a significant consideration for rail workers who may encounter live electrical elements.

Lastly, the outsoles of these boots are often crafted to be slip-resistant, which provides crucial stability and helps prevent slips and falls on the unpredictable surfaces of railroad environments.

Rubber Boots: Waterproof and Chemical-Resistant

Rubber boots serve as essential protective gear for workers in the railroad ballast industry by guarding against water intrusion and hazardous chemicals. These boots are crafted from a specialized rubber material that is naturally impervious to water, ensuring that workers’ feet stay dry, even in wet and muddy conditions.

Additionally, the rubber material provides a strong barrier against various harmful chemicals encountered on the job, such as herbicides, pesticides, and fertilizers.

These substances can cause skin irritation or chemical burns, but the chemical-resistant properties of rubber prevent direct contact and potential harm. Here’s a breakdown of the protective features of rubber boots:

| Feature | Protection Provided | Benefit to Workers |

| Waterproof Material | Prevents water from penetrating the boot | Keeps feet dry and protects against water damage |

| Chemical Resistance | Acts as a barrier against harmful chemicals | Prevents skin contact with irritants and burns |

| Non-slip Sole | Enhances traction on slippery surfaces | Reduces the risk of slips and falls |

Furthermore, these boots are designed with non-slip soles to provide better traction on uneven and slippery surfaces, a common hazard in this industry. This feature significantly lowers the risk of accidents, contributing to a safer work environment.

Overall, rubber boots not only offer substantial protection from environmental hazards but also help maintain high productivity by reducing the risk of injuries. Workers and employers alike recognize the indispensable role that these boots play in ensuring safety and efficiency on the railroad ballast.

Hiking Boots: Comfort and Traction on the Ballast

| Feature | Description | Benefit |

| Robust Rubber Outsoles | Made from durable rubber with deep lugs. | Provides enhanced grip and traction on loose and uneven surfaces. |

| Cushioned Midsoles | Constructed from EVA or polyurethane foam. | Offers shock absorption, reducing foot fatigue and discomfort. |

| Ankle Support | High-top design encasing the ankle. | Prevents ankle injuries by supporting the joint on uneven ground. |

| Adaptive Lacing | Adjustable lacing systems for a secure fit. | Improves balance and stability, ensuring safety on the ballast. |

By understanding these features, hikers can choose boots that will provide both comfort and reliable traction while walking on challenging railroad ballast, enhancing their overall hiking experience.

Wellington Boots: Convenience and Protection Against Wet Conditions

Wellington boots are indispensable for workers on railroad ballast, offering both convenience and robust protection against wet conditions. Here’s how they excel:

- Waterproof Materials: Wellington boots are crafted from rubber or PVC, creating an impermeable barrier against water. This is crucial for railroad ballast workers who are frequently exposed to moisture, ensuring their feet remain dry and safe from water-related discomfort or health issues.

- High Shaft Design: The design includes a high shaft that covers the entire foot up to the calf, providing extensive protection not only against moisture but also from mud, debris, and small rocks typical in railroad environments.

- Slip-Resistant Soles: The soles are engineered with deep treads that offer exceptional grip on slippery, uneven surfaces like those found on railroad tracks, enhancing safety by reducing the risk of slips and falls.

- Durability: Made to withstand tough conditions, Wellington boots are durable and resistant to wear and tear from constant exposure to harsh elements, which makes them a cost-effective choice for the demanding environment of railroad work.

- Ease of Use: These boots are designed for ease, with a simple slip-on, slip-off style that saves time and effort for workers who may need to change footwear quickly. The lightweight nature and comfort of the boots also allow for prolonged wear without discomfort.

Conclusion

In the world of railroad work, choosing the right boots is not just about comfort—it’s about maintaining a steadfast guard against the unpredictable terrain of railroad ballast. Workers who tread along these rocky paths day after day need footwear that embodies the trifecta of durability, protection, and comfort. The best boots for this job, from steel-toe to composite-toe, offer an impregnable shield against the jagged edges of ballast and the heavy burdens of the rails.

These boots are crafted from robust materials designed to endure the relentless wear and tear of the railroad environment. Features like waterproofing and insulation adapt to varying climates, ensuring that your feet stay dry and warm, regardless of weather extremes. Moreover, the right boots balance protection with lightweight designs to minimize fatigue, empowering workers to navigate the tracks with confidence and agility.

As you lace up boots tailored for the rigors of railroad ballast, think of them not just as footwear, but as a fortress for your feet—a base from which you can steadfastly and safely perform at your best. For every rail worker, the journey to a secure and comfortable shift starts from the ground up.